Spindle RPM

- Digital Makino

- Machine Technology

- Support

- Events

- Resources

- About Us

- Press

- Select a Language

- Distributor Login

- Financing

- Request A Quote

- Find A Rep

- My Makino

- Careers

- Contact Us

- Why Makino?

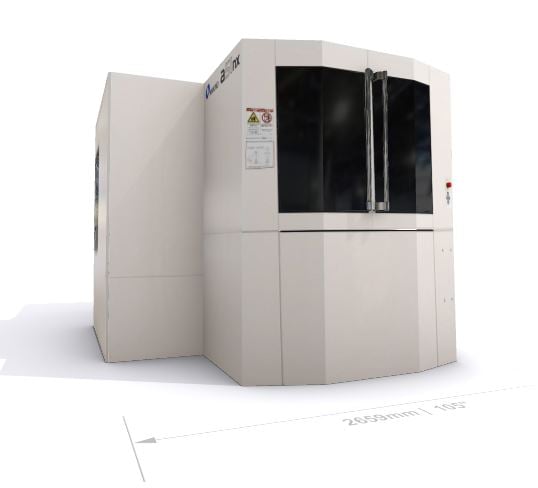

The Makino a51nx is a 400mm horizontal machining center that builds on the highly successful a51 platform with key high performance machining technologies that take productivity, accuracy and machine reliability to the next level.

The 14,000-rpm high-speed, high-power spindle features 240 Nm of torque, making it well suited for ferrous and non-ferrous part production.

1G axis acceleration and a standard direct-drive motor B-axis minimizes non-cut times, whereas a robust casting design and roller-type linear guides ensure the entire a51nx work envelope can be effectively utilized.

Additionally, one-piece way covers (X and Z) and a dual-supported tool-change arm provide the foundation for industry-leading reliability and high performance machining capability.

Spindle RPM

14,000 rpm (14K High Torque, 20K)

Spindle Taper

CAT40 (HSK-63)

Rapid Traverse

60,000 mm/min

Cutting Feedrate

50,000 mm/min

Maximum Workpiece

ø630 mm x 900 mm

Maximum Payload

400 kg

ATC Capacity

60 tools (optional 40, 134, 219, 313)

Tool to Tool

0.9 secs

Chip to Chip

2.2 secs

Maximum Tool Length (Cat)

430 mm

Maximum Tool Length HSK

420 mm

Maximum Tool Diameter

170 mm

Maximum Tool Weight

12 kg

Spindle RPM:

14,000 rpm (14K High Torque, 20K)

Spindle Taper:

40 (HSK-63)

Rapid Traverse:

2,362 ipm

Cutting Feedrate:

1,968ipm

Maximum Workpiece:

ø24.8" x 35.4"

Maximum Payload:

880 lbs

ATC Capacity:

60 tools (optional 40, 134, 219, 313)

Tool to Tool:

0.9 secs

Chip to Chip:

2.2 secs

Maximum Tool Length (Cat):

16.9"

Maximum Tool Length HSK:

16.5"

Maximum Tool Diameter:

6.7"

Maximum Tool Weight:

26.4 lbs

© 2025, Makino Inc. All rights reserved.