- Digital Makino

- Machine Technology

- Support

- Events

- Resources

- About Us

- Press

- Select a Language

- Tech Expo

- Distributor Login

- Financing

- Request A Quote

- Find A Rep

- My Makino

- Careers

- Contact Us

- Why Makino?

.jpg) Thanks to the advent of real-time production software and hardware, getting the most out of a shop floor environment is just a click away. When multiple machines are connected on a single network, manufacturers can use data-monitoring software to store and analyze high volumes of actionable machine data in real time, eliminating the need for manual data collection.

Thanks to the advent of real-time production software and hardware, getting the most out of a shop floor environment is just a click away. When multiple machines are connected on a single network, manufacturers can use data-monitoring software to store and analyze high volumes of actionable machine data in real time, eliminating the need for manual data collection.

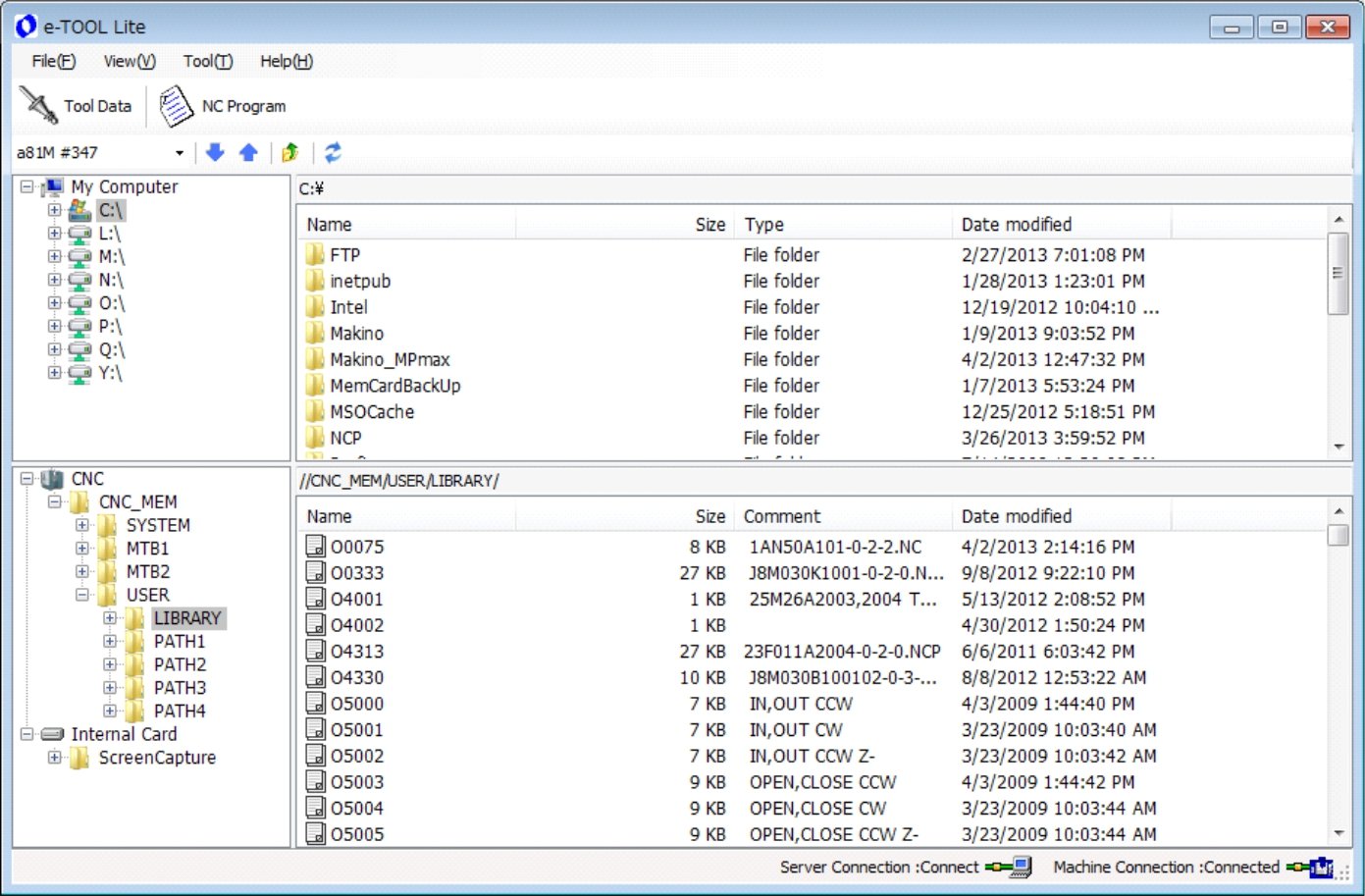

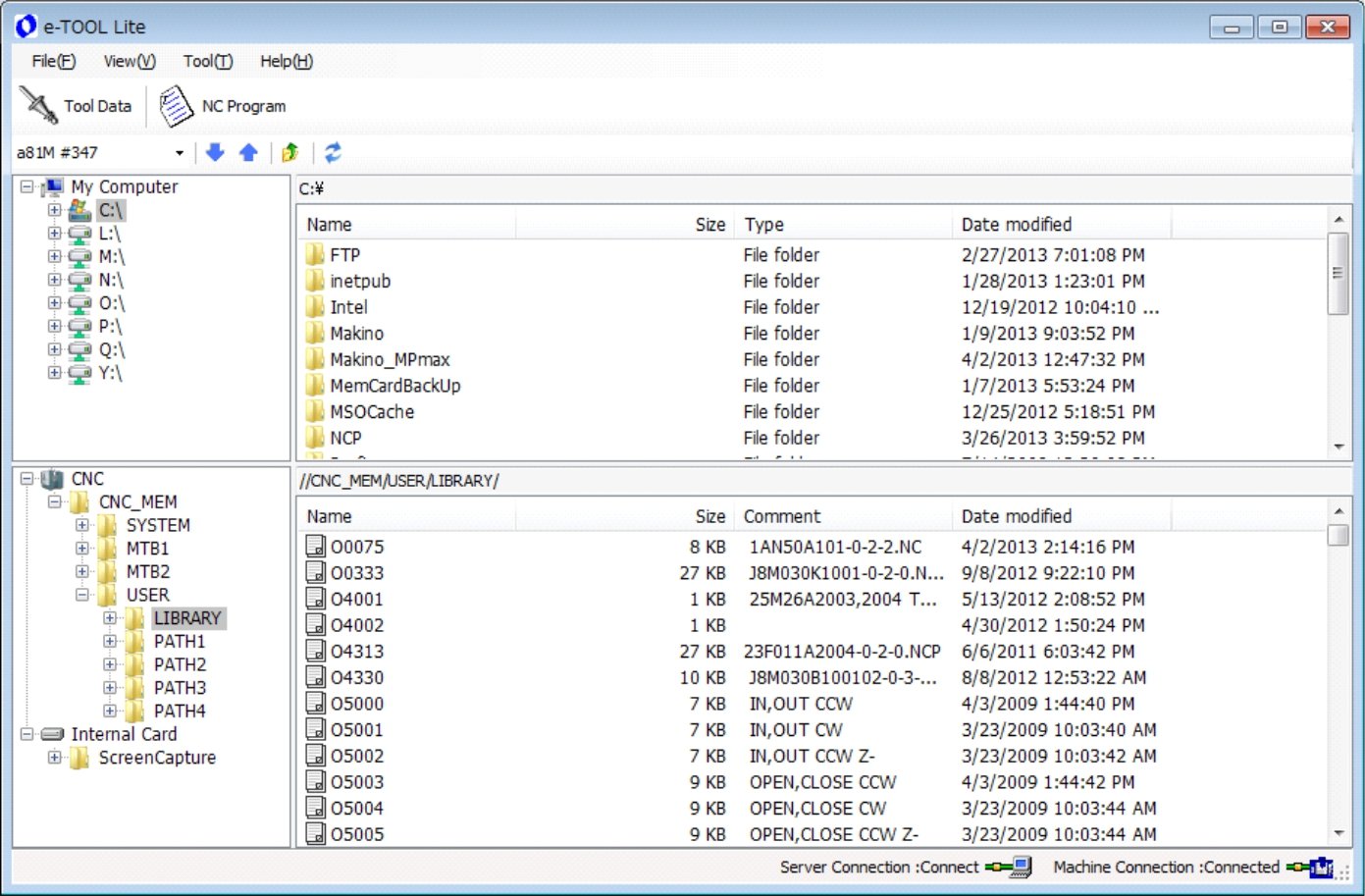

Defines a part as well as the group of NC programs needed to make that part. The remote monitoring system scans the programs and then determines whether the machine has the tools it needs to make that part. If it doesn't, the system notifies the operator and shares what tools it needs.

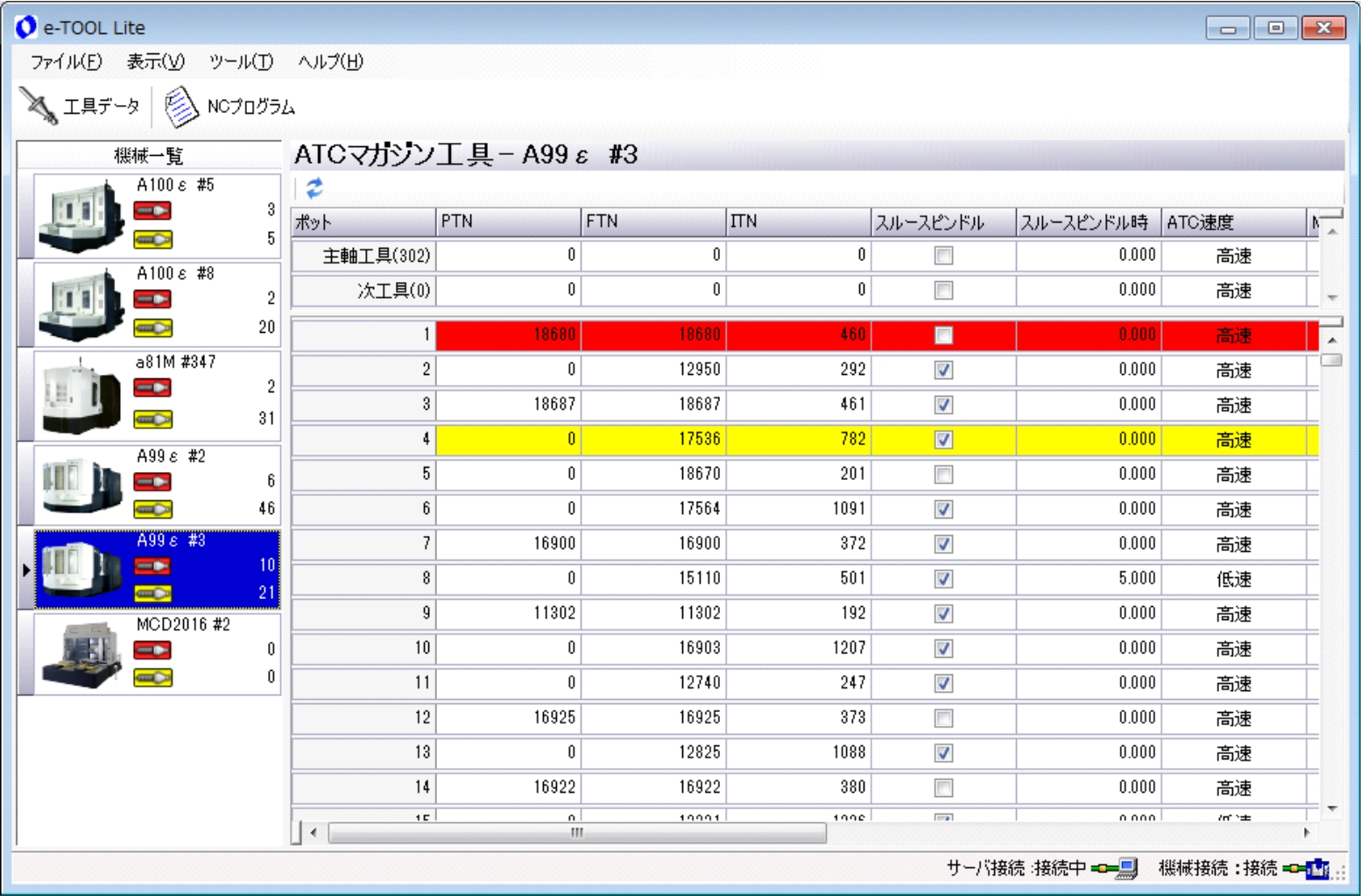

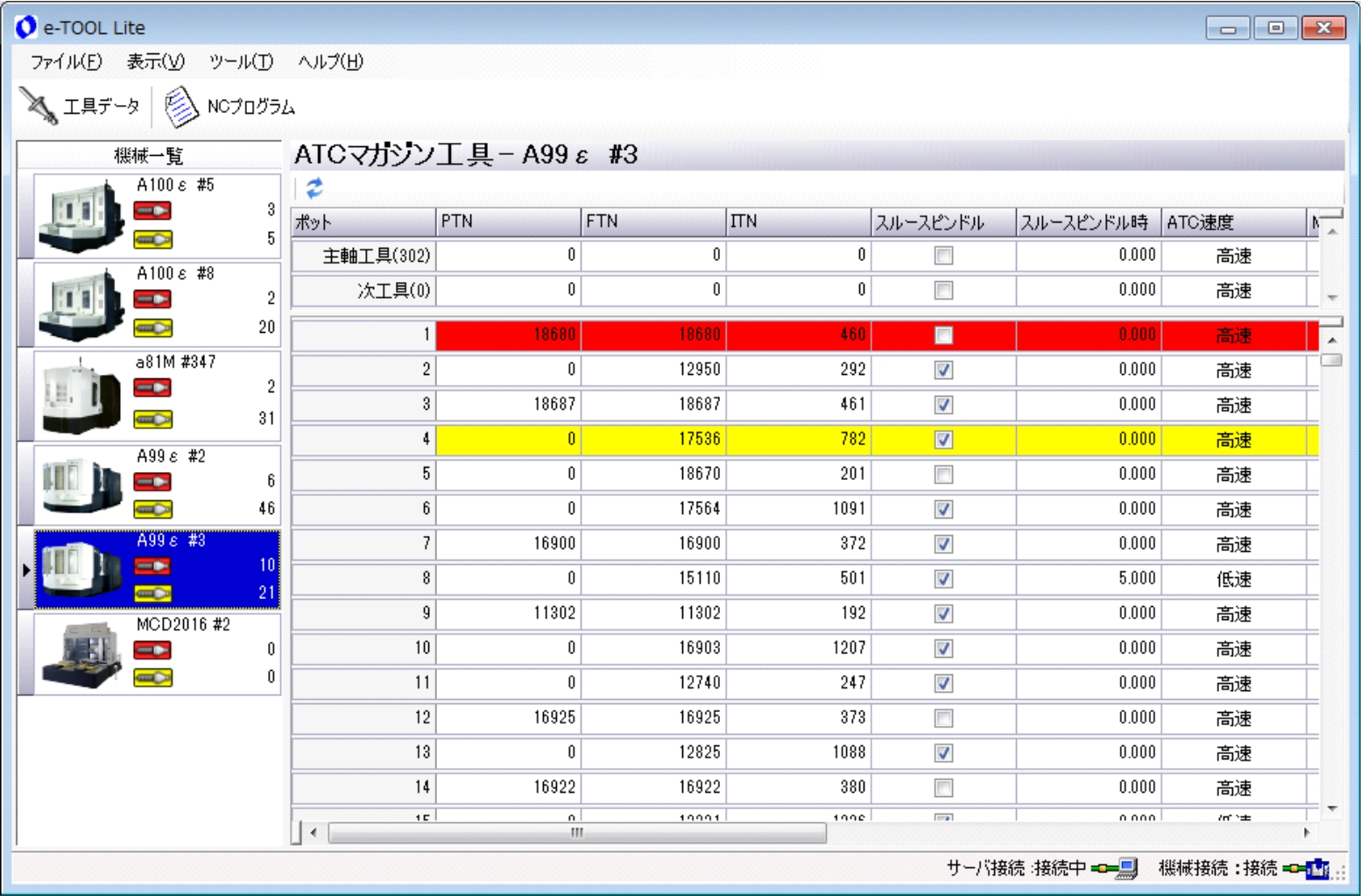

Monitors tool length, diameter,offset and alarm data.This actionable data can help maximize tooling life cycle. It also helps the system know what tools are available at each machine. Manufacturers can use the data to find replacement tools before the process stops due to tool shortage.

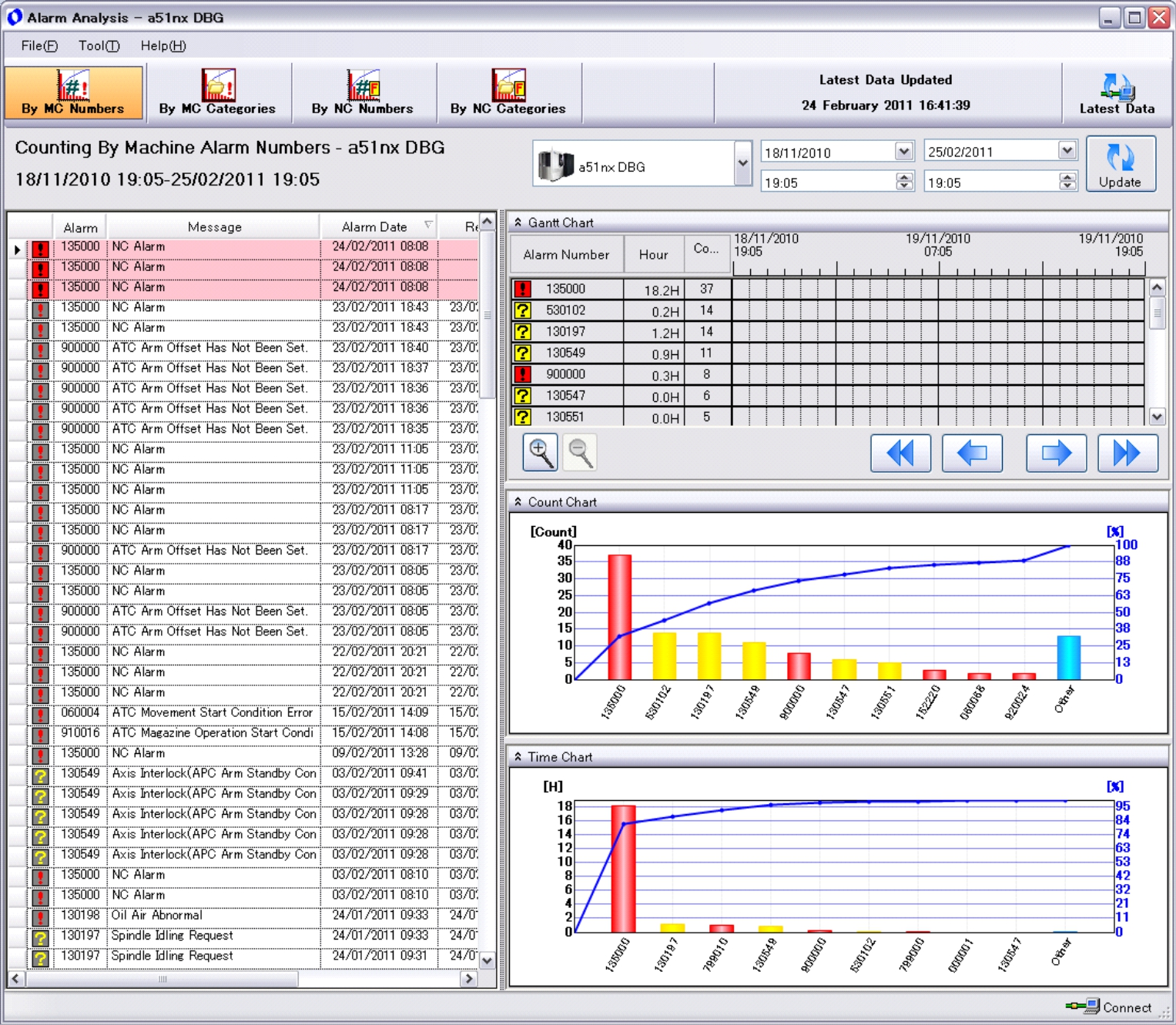

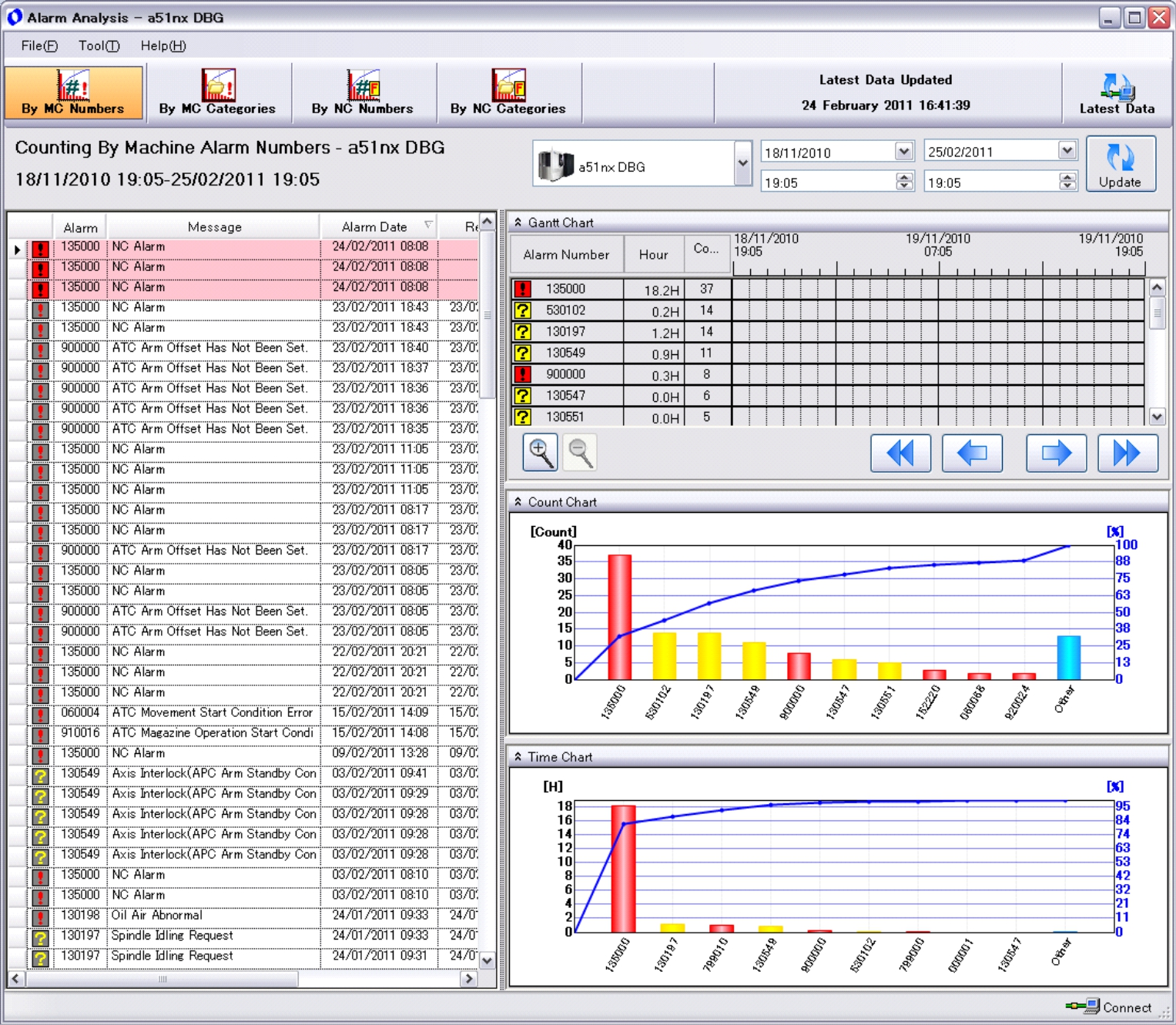

Real time data monitoring tracks every occurrence of each alarm on each machine. Personnel can bring up details of an alarm and its history, or see the top 10 alarms that went off in a specific time period. Personnel can also see the alarms that have caused the most downtime. This provides insight into issues with the machine so users can start proactive maintenance for alarms whose frequency have increased over time.

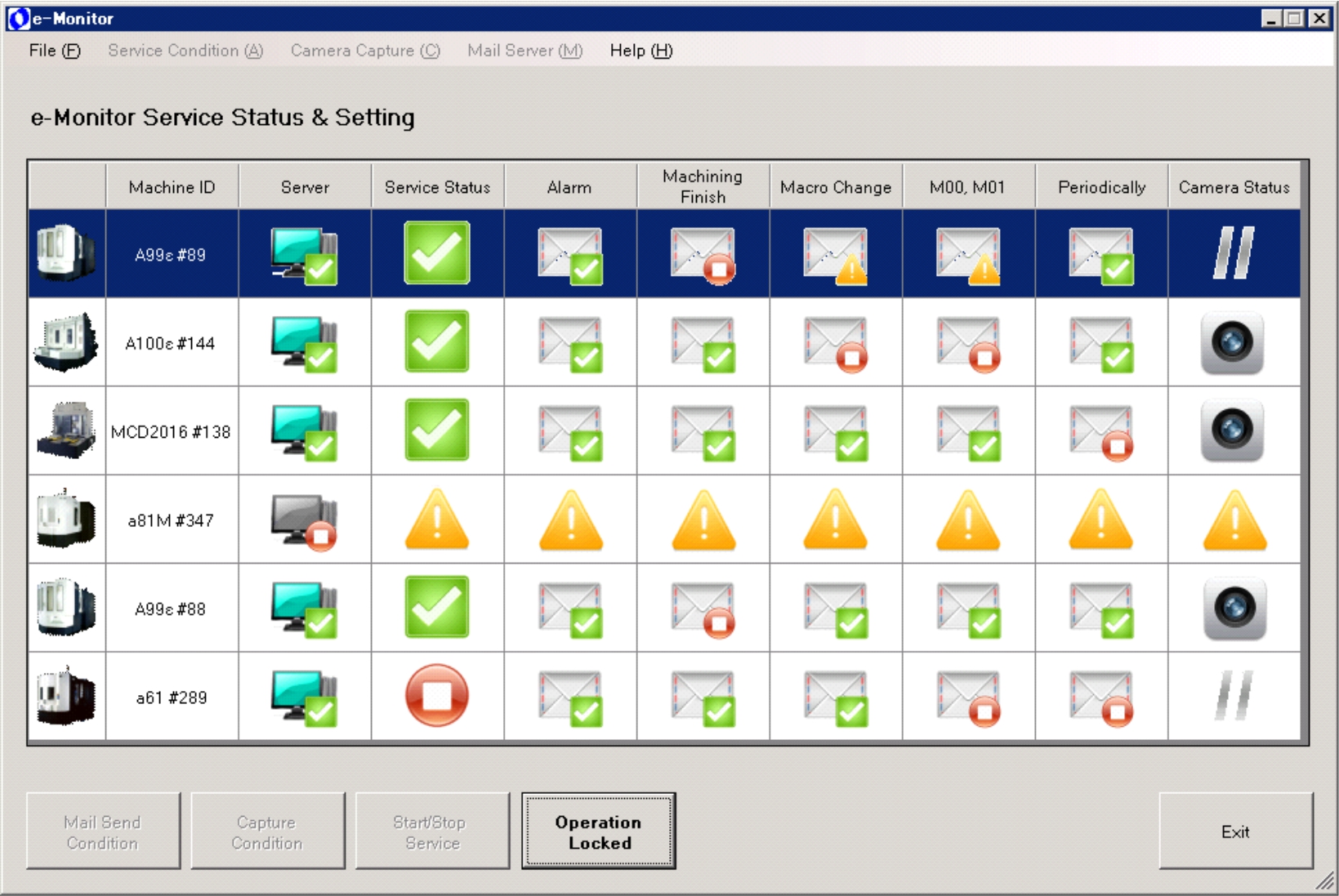

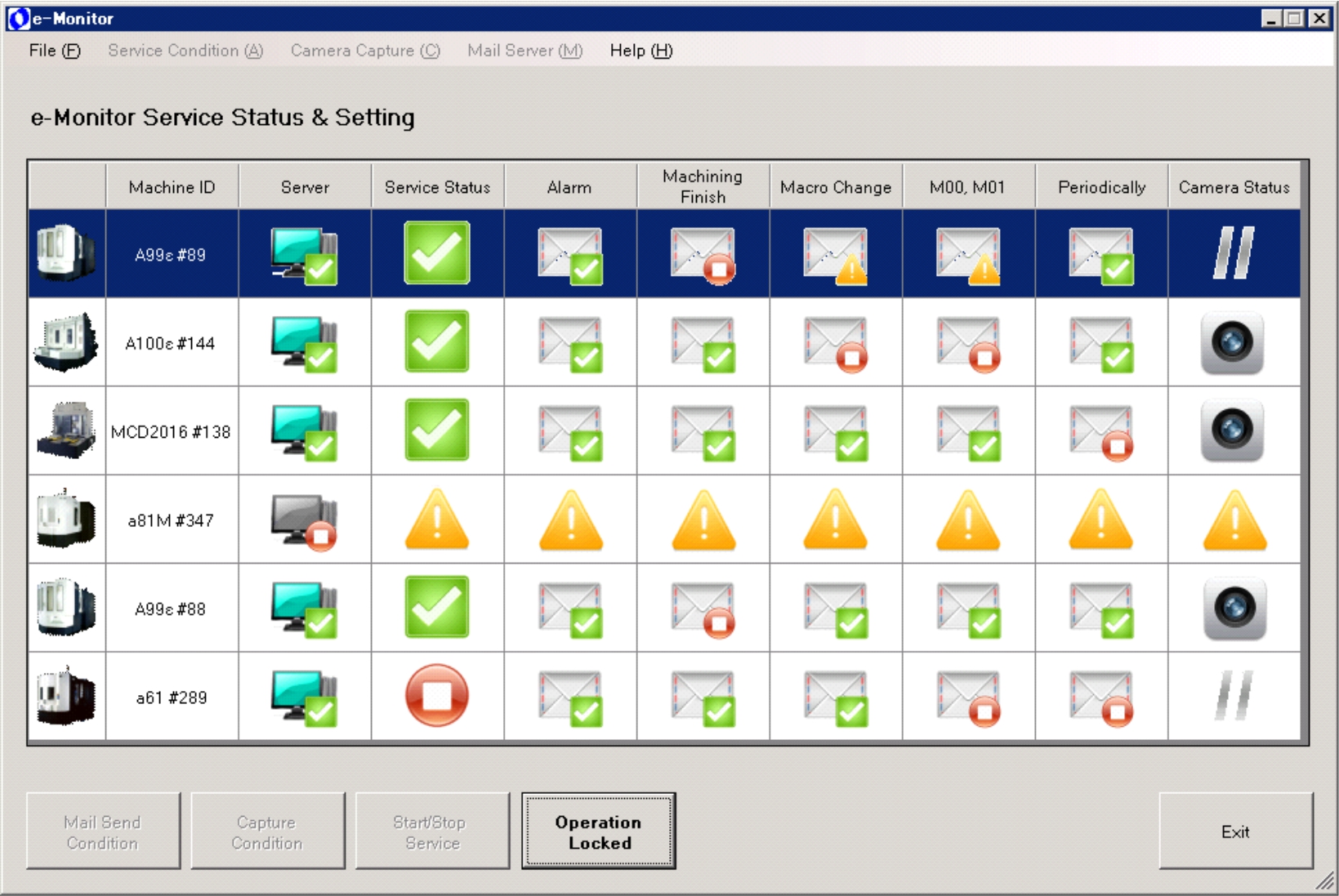

When a machine alarm activates, e-mail and/or text messages can notify personnel. This feature enables operators to deliver detailed machine status information to their service department, including alarm descriptions and images of the work zone. This information can help them address problems as they occur, and can dramatically improve productivity and process control. Personnel can choose to get notifications in the office, on the road or at home and across a variety of devices. As with all remote communications, a company's IT department typically determines how and where this accessibility occurs.

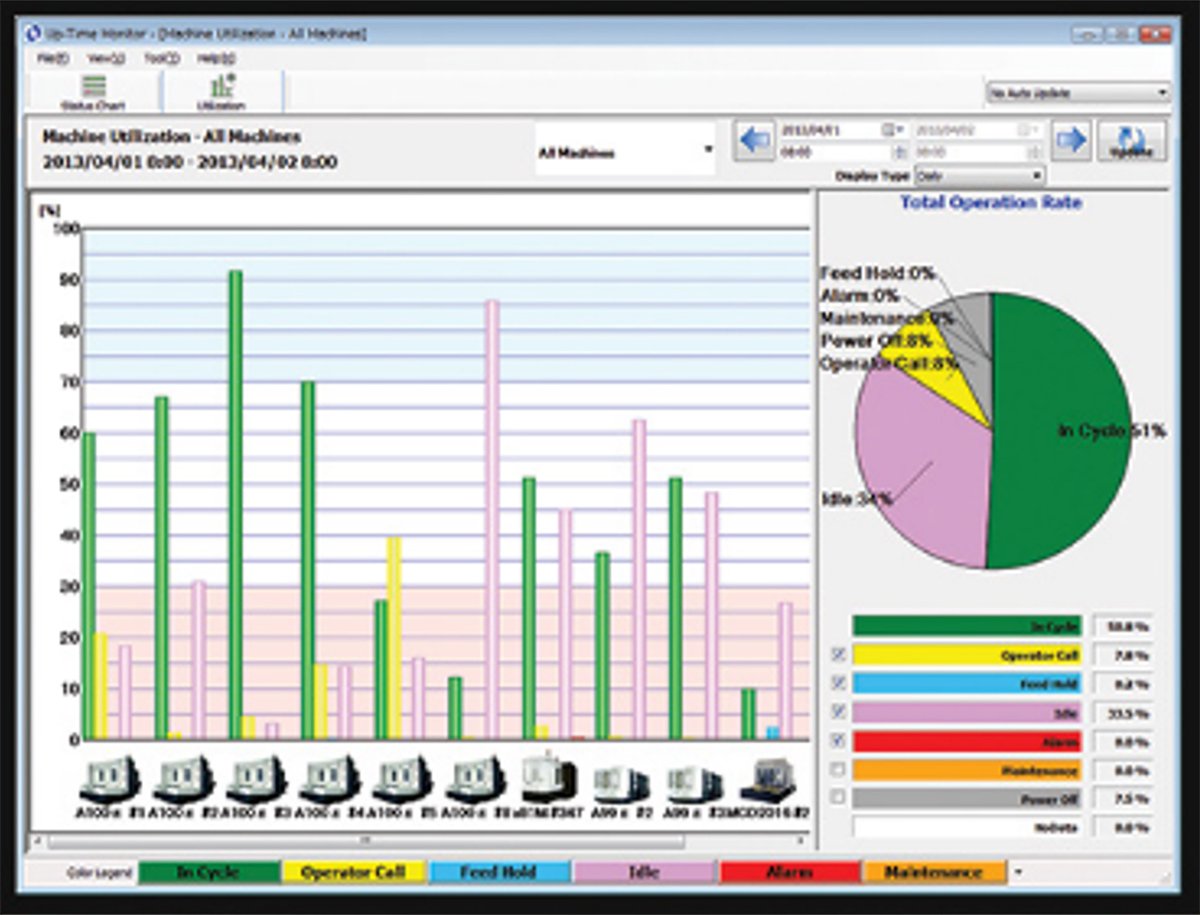

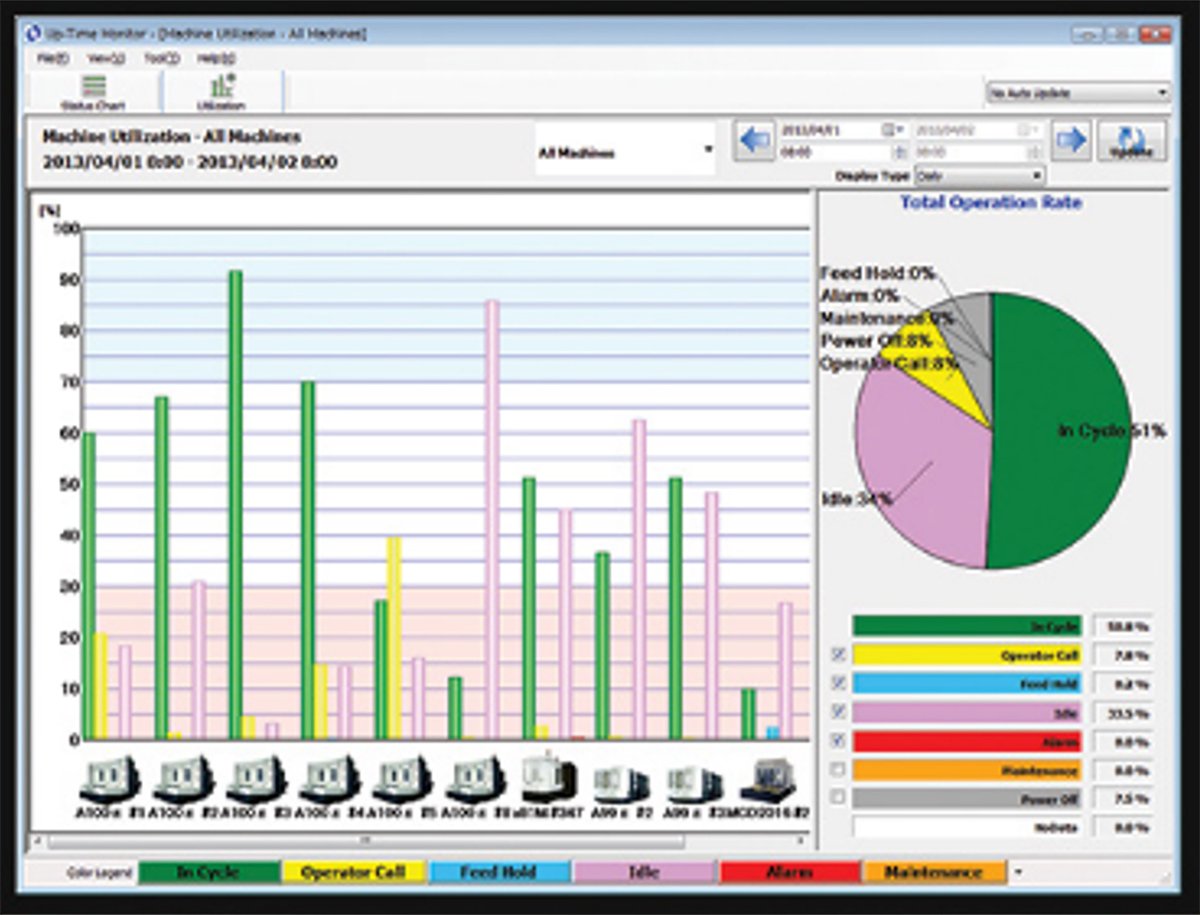

Displays how much time the machine has been in cycle or out of cycle during a specified time period. Also displays spindle cut time (the time the machine spindle makes chips), allowing full efficiency analysis. Keeping track of machine utilization is a key element of real-time production monitoring.

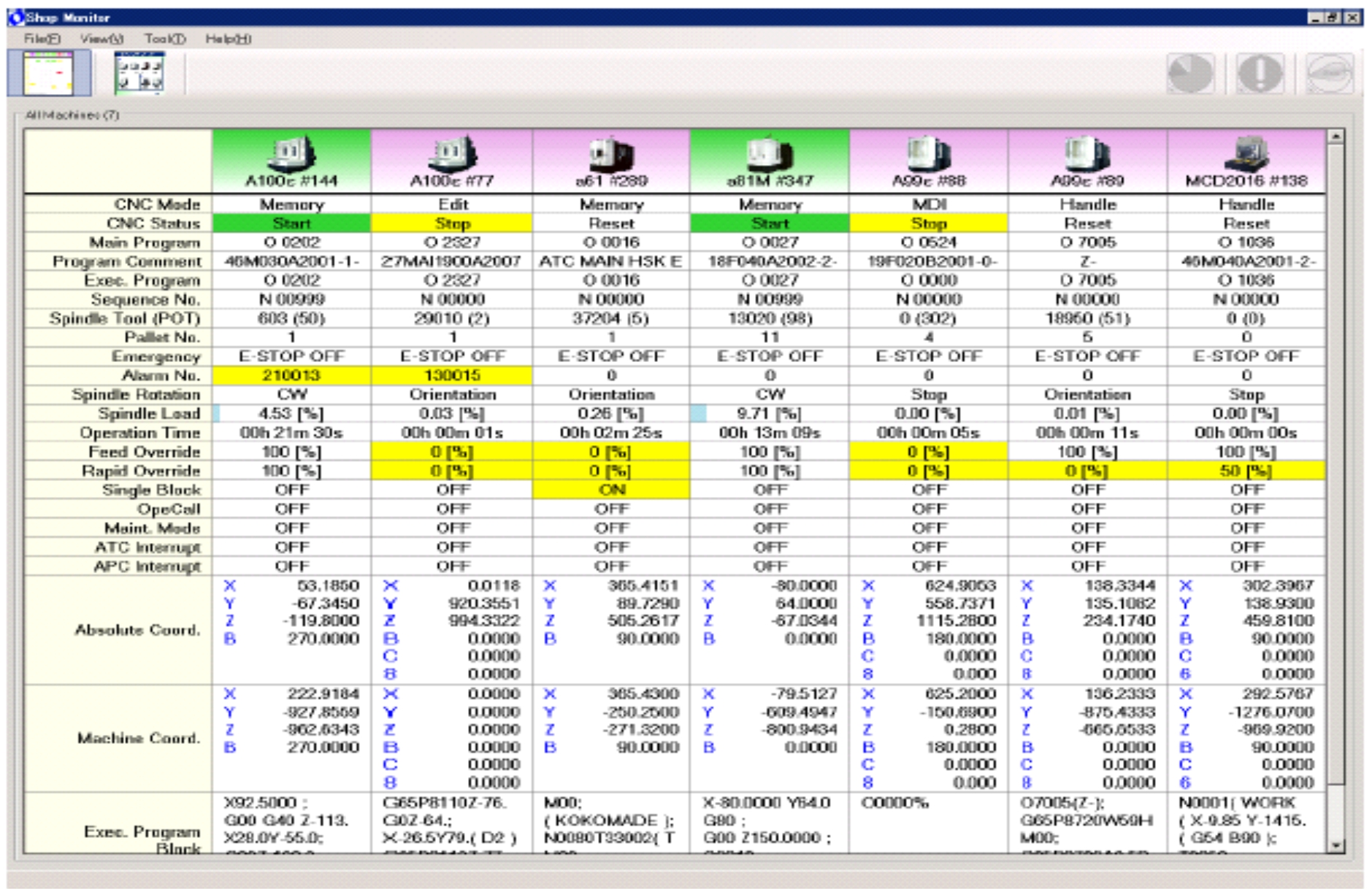

Displays the state of each machine, specifically whether or not it is running, by displaying “in cycle,” “out of cycle” and any alarms - all shown in real time. These alerts are recorded for later analysis. The alarm analysis feature lets personnel retrieve additional information about alarms, including how often they occur.

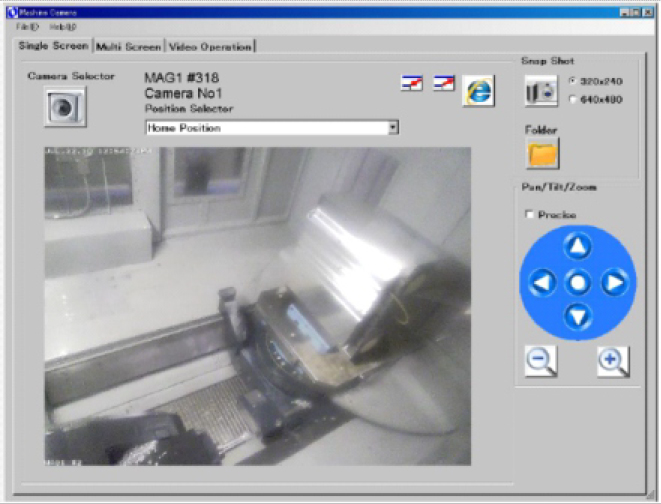

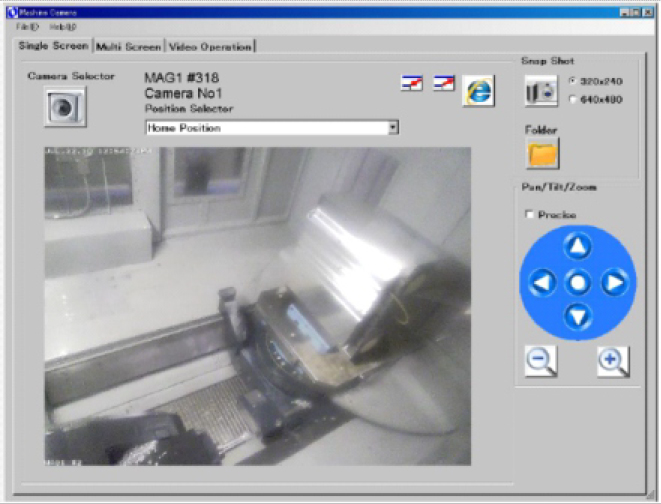

On camera-equipped machines, personnel can capture an internal view of the work zone—making it easier to solve processing errors before they affect part quality, and helpful in the event of repair. Operators and management can use remote viewing to track and respond to processes as they occur, without interrupting other day-to-day activities. A company's IT department can determine the extent of remote network monitoring for personnel based on security protocols, specifically whether to allow it on laptops, tablets or smartphones.

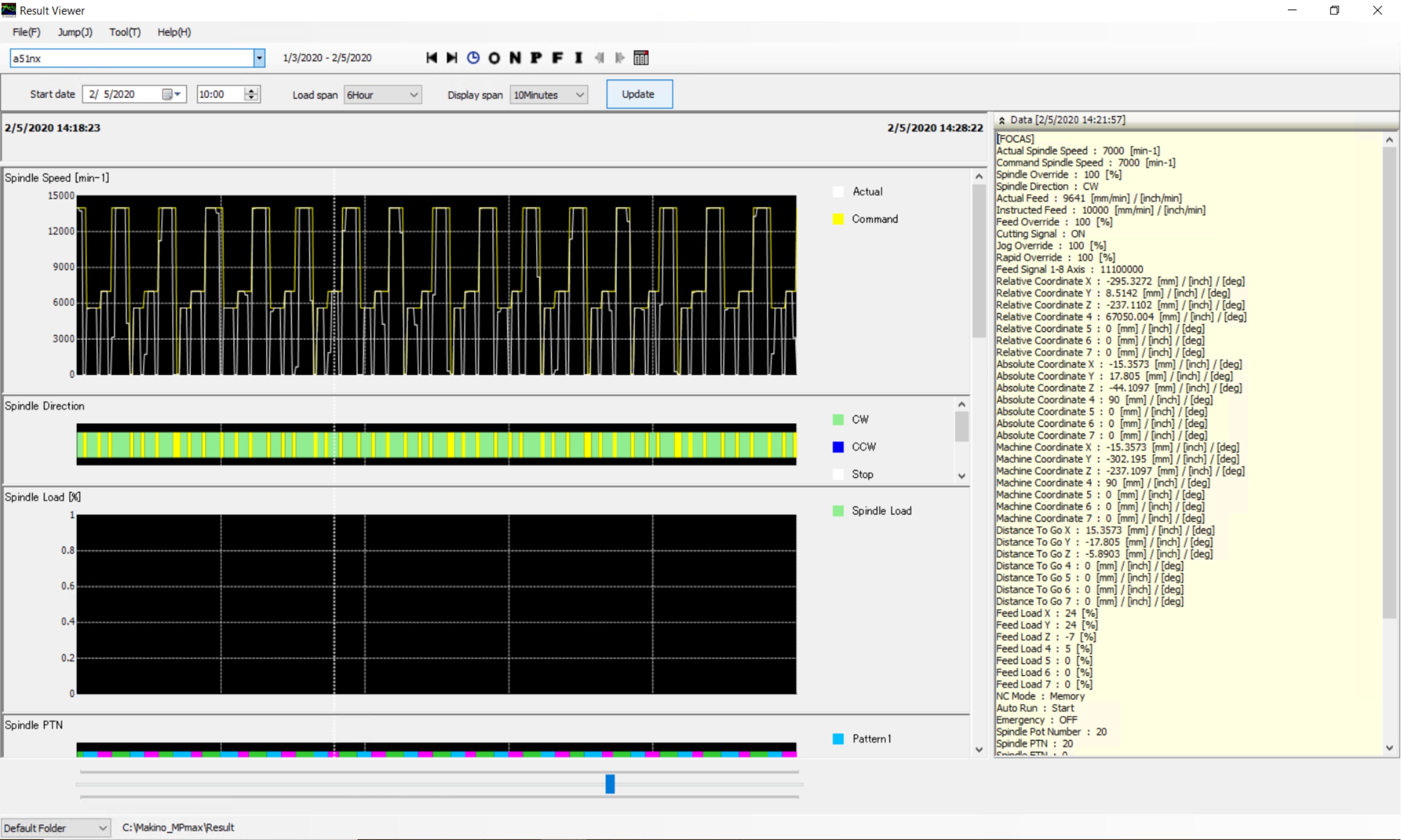

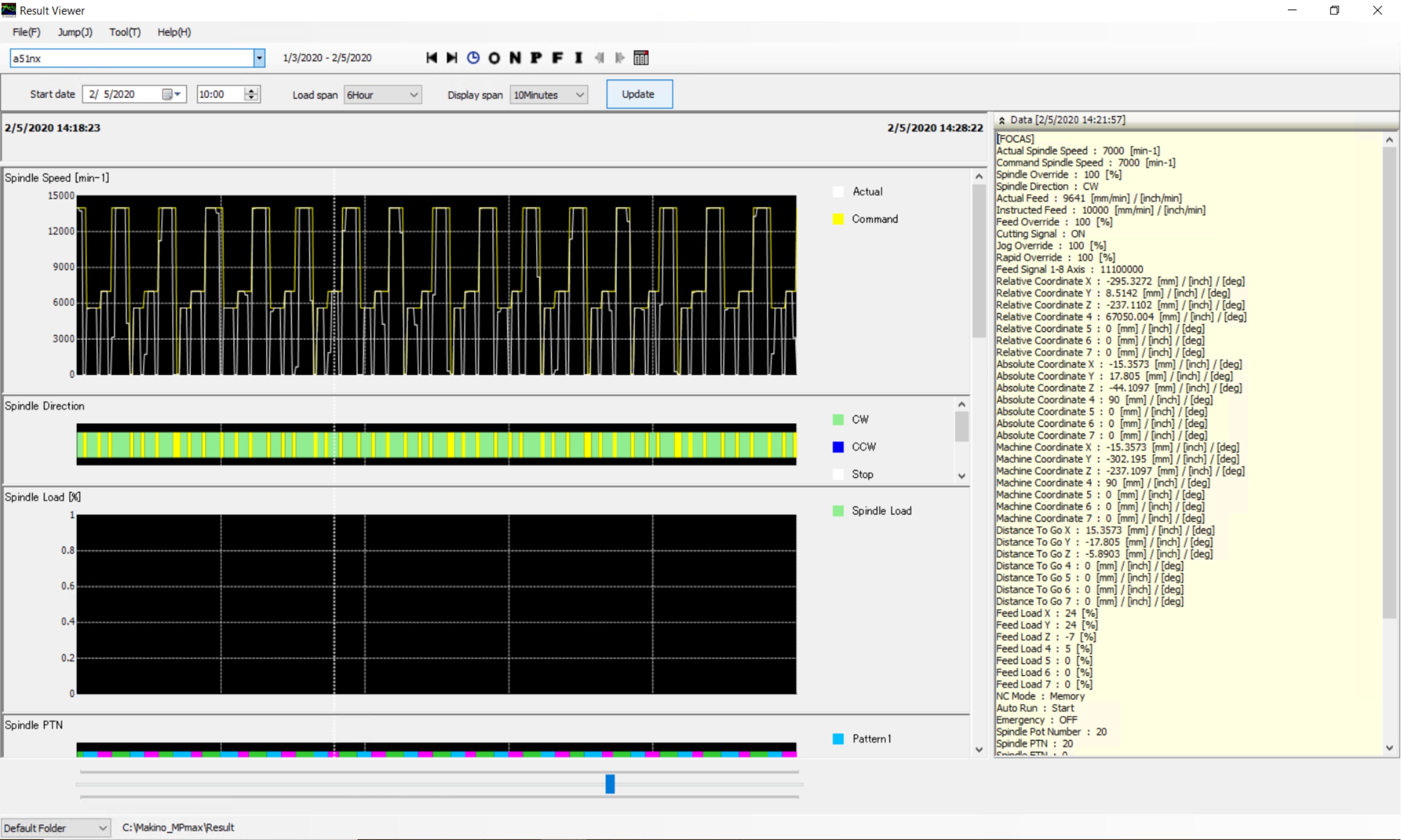

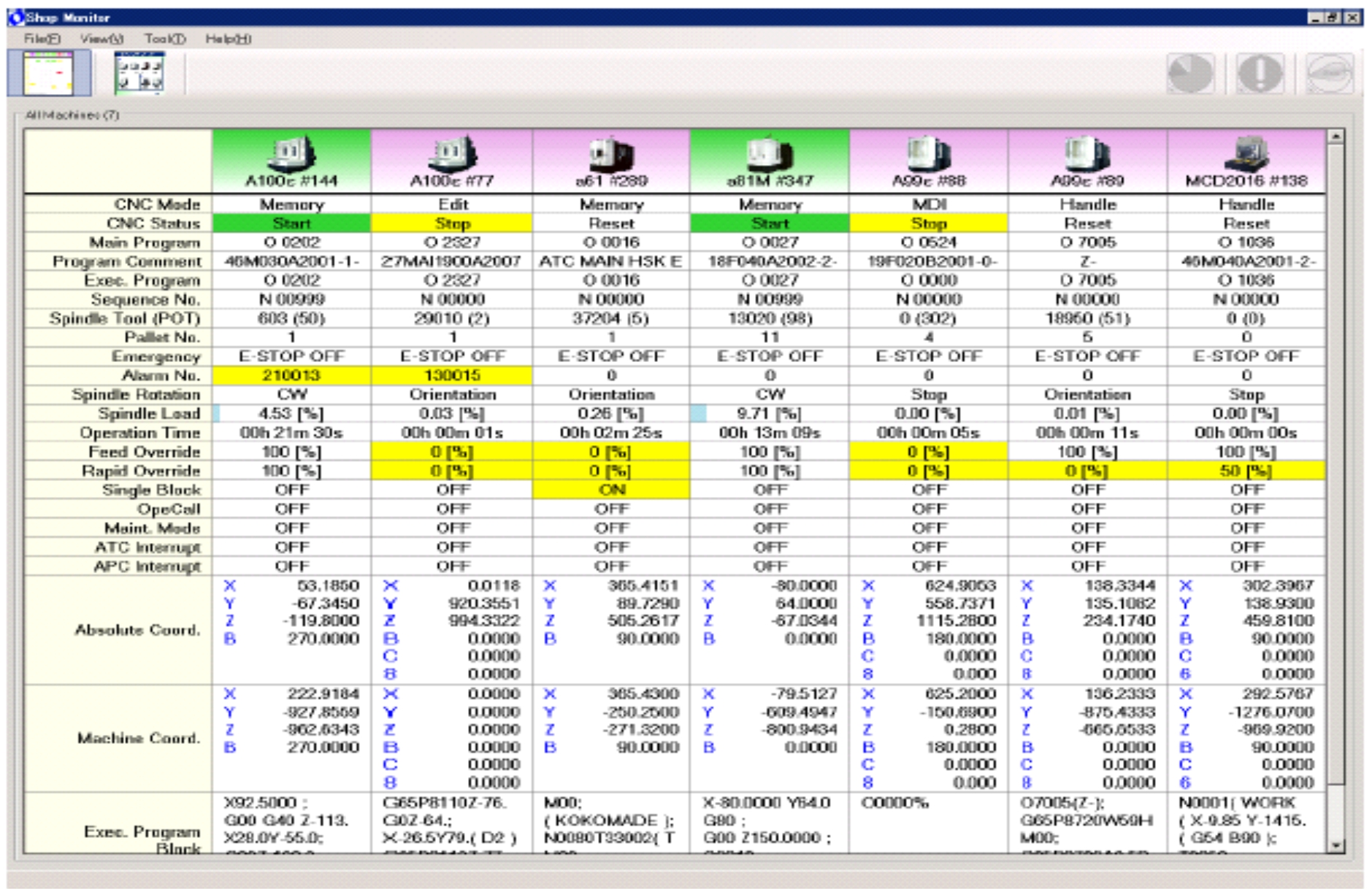

Tracks spindle load, axis loads, feed/speed, active program, spindle tool, alarms and other factors related to machine operation. The data is recorded and archived, and users can sort by spindle tool number, alarm number and active program. That way, if there's a performance problem or alarm, the data can lead to accurate resolutions. Additionally, if there is a spindle incident, personnel can see exactly where it happened in the program. Some types of software record the incident to the exact line number in the NC program where it happened, helping the operator easily adjust the cutting parameters.

Defines a part as well as the group of NC programs needed to make that part. The remote monitoring system scans the programs and then determines whether the machine has the tools it needs to make that part. If it doesn't, the system notifies the operator and shares what tools it needs.

Monitors tool length, diameter,offset and alarm data.This actionable data can help maximize tooling life cycle. It also helps the system know what tools are available at each machine. Manufacturers can use the data to find replacement tools before the process stops due to tool shortage.

Real time data monitoring tracks every occurrence of each alarm on each machine. Personnel can bring up details of an alarm and its history, or see the top 10 alarms that went off in a specific time period. Personnel can also see the alarms that have caused the most downtime. This provides insight into issues with the machine so users can start proactive maintenance for alarms whose frequency have increased over time.

When a machine alarm activates, e-mail and/or text messages can notify personnel. This feature enables operators to deliver detailed machine status information to their service department, including alarm descriptions and images of the work zone. This information can help them address problems as they occur, and can dramatically improve productivity and process control. Personnel can choose to get notifications in the office, on the road or at home and across a variety of devices. As with all remote communications, a company's IT department typically determines how and where this accessibility occurs.

Displays how much time the machine has been in cycle or out of cycle during a specified time period. Also displays spindle cut time (the time the machine spindle makes chips), allowing full efficiency analysis. Keeping track of machine utilization is a key element of real-time production monitoring.

Displays the state of each machine, specifically whether or not it is running, by displaying “in cycle,” “out of cycle” and any alarms - all shown in real time. These alerts are recorded for later analysis. The alarm analysis feature lets personnel retrieve additional information about alarms, including how often they occur.

On camera-equipped machines, personnel can capture an internal view of the work zone—making it easier to solve processing errors before they affect part quality, and helpful in the event of repair. Operators and management can use remote viewing to track and respond to processes as they occur, without interrupting other day-to-day activities. A company's IT department can determine the extent of remote network monitoring for personnel based on security protocols, specifically whether to allow it on laptops, tablets or smartphones.

Tracks spindle load, axis loads, feed/speed, active program, spindle tool, alarms and other factors related to machine operation. The data is recorded and archived, and users can sort by spindle tool number, alarm number and active program. That way, if there's a performance problem or alarm, the data can lead to accurate resolutions. Additionally, if there is a spindle incident, personnel can see exactly where it happened in the program. Some types of software record the incident to the exact line number in the NC program where it happened, helping the operator easily adjust the cutting parameters.