- Digital Makino

- Machine Technology

- Support

- Events

- Resources

- About Us

- Press

- Select a Language

- Tech Expo

- Distributor Login

- Financing

- Request A Quote

- Find A Rep

- My Makino

- Careers

- Contact Us

- Why Makino?

Predict Your Machine Health with Makino’s MHmax Predictive Analytics

One study shows that unplanned downtime can cost a company as much as $260,000 per hour.* While these expenses can greatly vary depending on the size of each shop, the factors which determine the calculation remain the same.Companies should look at how much profit, capacity, and productivity are lost while labor costs per unit, overtime costs, and maintenance costs increase.

One study shows that unplanned downtime can cost a company as much as $260,000 per hour.* While these expenses can greatly vary depending on the size of each shop, the factors which determine the calculation remain the same.Companies should look at how much profit, capacity, and productivity are lost while labor costs per unit, overtime costs, and maintenance costs increase.

The Hidden Costs of Unplanned Downtime

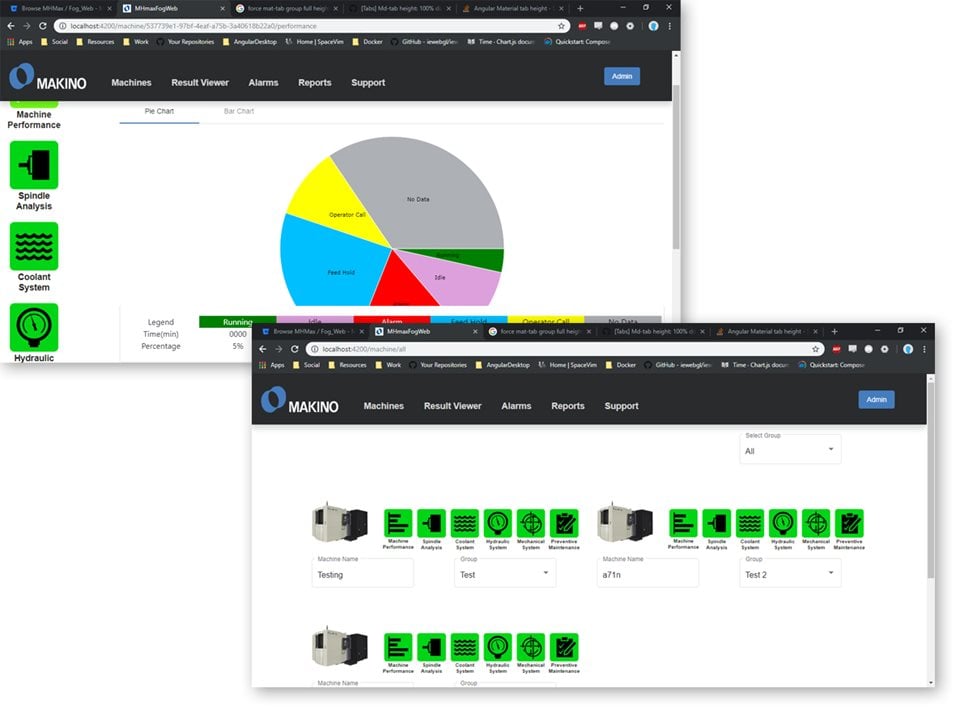

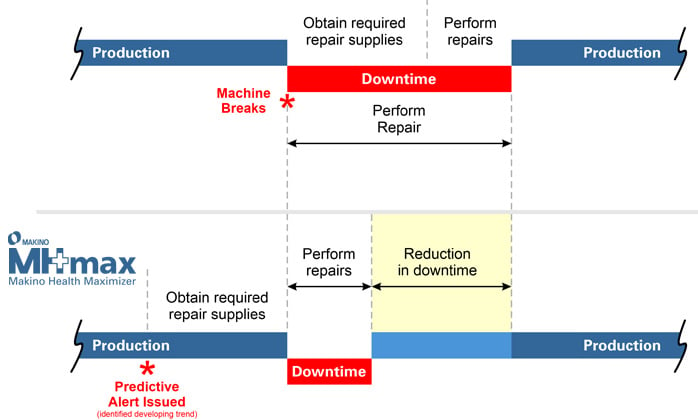

MHmax machine health monitoring software exists to allow for planned machine service before the machine unexpectedly goes down - significantly reducing downtime.

MHmax machine health monitoring software exists to allow for planned machine service before the machine unexpectedly goes down - significantly reducing downtime.

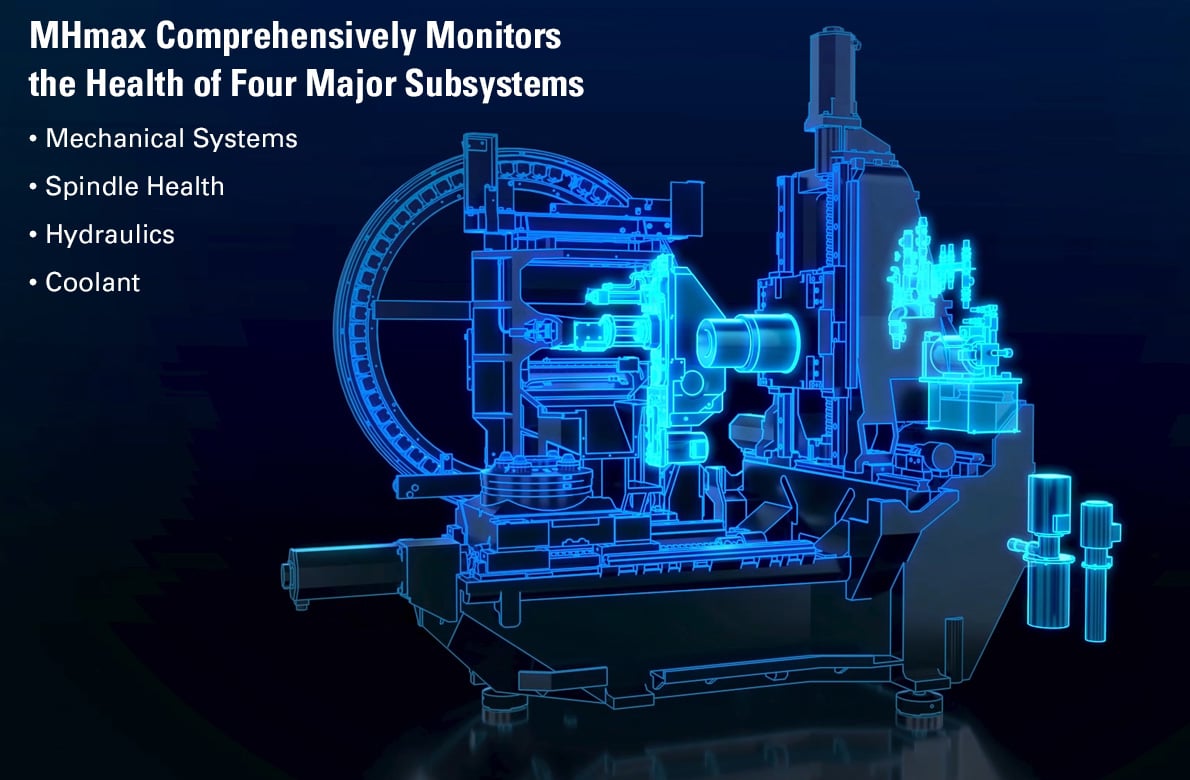

Relying on 15 years of customer support data in different production scenarios, Makino engineers identified the leading causes of unplanned downtime and the important warning signs to maximize machine performance.

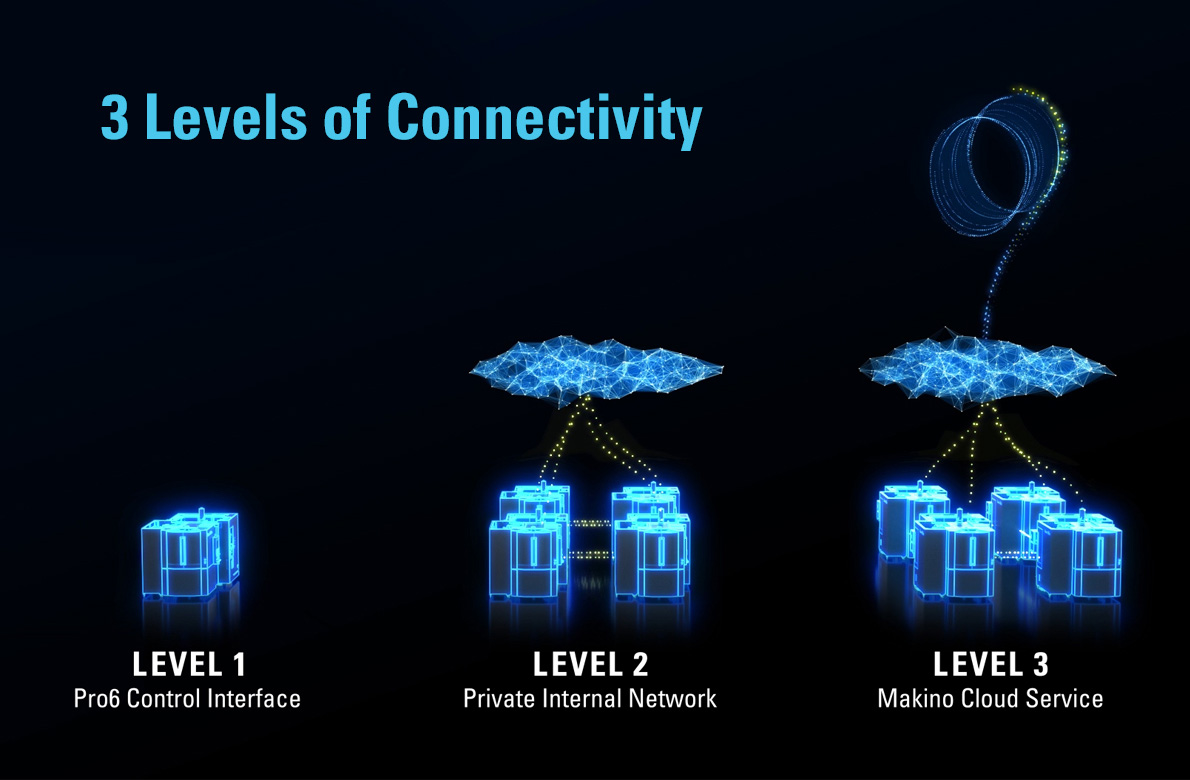

Relying on 15 years of customer support data in different production scenarios, Makino engineers identified the leading causes of unplanned downtime and the important warning signs to maximize machine performance. Makino highly values your privacy and data ownership, so MHmax offers three levels of IoT connectivity to support predictive maintenance - where you control access to your data.

Makino highly values your privacy and data ownership, so MHmax offers three levels of IoT connectivity to support predictive maintenance - where you control access to your data.