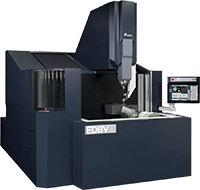

Table:

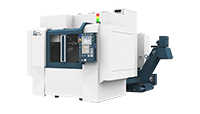

D200Z

The D200Z 5 axis vertical machine center combines extreme speeds to slash manufacturing times along with the precision for tighter tolerances, flawless blends and matches in complex 3-D contoured workpieces. With its small, super high-speed axes, the D200Z is ideal for small die/mold, medical parts and...