- Digital Makino

- Machine Technology

- Support

- Events

- Resources

- About Us

- Press

- Select a Language

- Distributor Login

- Financing

- Request A Quote

- Find A Rep

- My Makino

- Careers

- Contact Us

- Why Makino?

Skills assessment to determine current knowledge

Advanced control overview

Electronic machine manual navigation and overview

My Makino introduction and enrollment

Researching and submitting online part orders

FANUC features and troubleshooting

Control restoration and backup

Functions used during machining operations

Programming for maintenance activities

Machine networking and PC fundamentals

Remote technical support setup

Makino service departments introduction

Spindle troubleshooting

Axes troubleshooting

Reference adjustments

Surface finish troubleshooting

Post crash machine evaluation

Complete ball screw replacement

Magazine alignments post-crash

Hydraulic and pneumatic troubleshooting

Broken Tool Sensor (BTS) adjustments and troubleshooting

Foundations for precision machining

Machine geometry introduction

Inspecting machine geometry

Interpreting machine geometry inspection reports

Multi point leveling and adjustment

Post-Crash inspections and reports

Hands on machine evaluation, geometry troubleshooting and adjustment

Machine performance history tracking

Machine performance audit

Preventative maintenance program planning

PM part number research and ordering

Spindle preventative maintenance inspections and component replacements

Coolant system preventative maintenance inspections

Conveyor chain tension adjustment and replacement

Coolant pump rebuild

Rotary union replacement

Machine belt adjustments and replacements

Matrix magazine inspections and adjustments

Chiller flushing after contamination

Machine filters overview

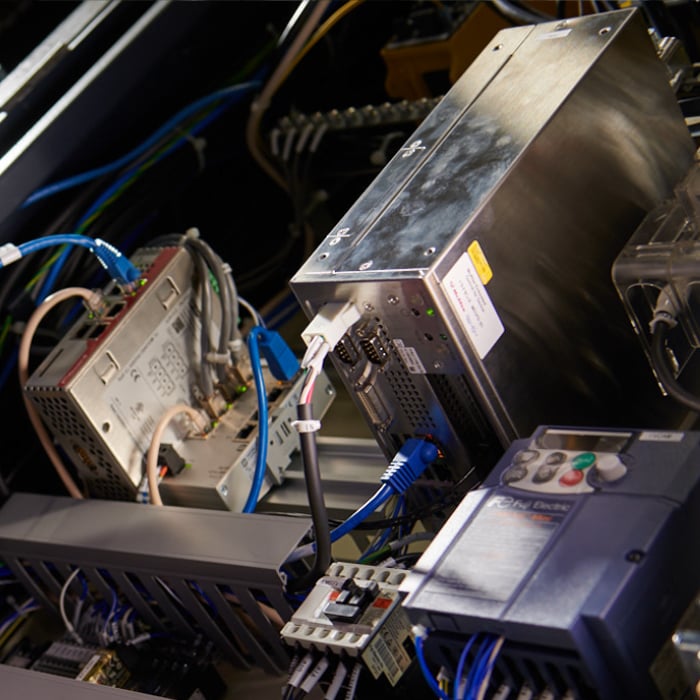

In depth machine tool electrical overview

Electrical component overview and identification

Alarm troubleshooting

FANUC alarm troubleshooting

Machine component electrical maps

Transformers and power supplies

ATC inverter parameters and adjustments

Spindle Chiller temperature sensor inspections

Machine switch types overview

In-depth hands-on troubleshooting

Spindle replacement

Drawbar rebuild

Spindle inspections post replacement

Table rebuild and adjustments

Machine rebuild parts research

Automatic Pallet Changer rebuild

Automatic Tool Changer replacement

Linear motion guide replacement

Final Program completion assessment