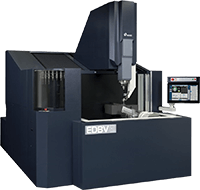

Sinker EDMs are ideal for hardened conductive materials and complex part details that are difficult to machine by other methods. While the electrical discharge machining process is usually slower than conventional milling, it excels at producing small deep features that are beyond the capability to mill to repeatable high accuracy.

Makino Sinker EDM machines speed up the spark erosion process by improving flushing and debris removal through an increase in the Z-Axis cycle jump rate four times faster and acceleration rate 30 times faster than previous technology. The enhancements to adaptive jump flushing and the all new higher power fully digital ES200A generator yield faster Sinker EDM machining speeds with significantly lower electrode wear.

The result: fewer electrodes required, faster cycle time with lower costs, and more uniform surface finishes that can eliminate the need for manual hand polishing.

Makino also gives you:

- Large HD Touchscreen control that works like a smartphone. Operators of all skill levels can use this streamlined interface that reduces machine training requirements. Only Makino can provide the advanced Hyper-i control that provides an identical productive interface for all Makino Sinker EDM, Wire EDM, and EDM Drilling machines, which further reduces training support needs.

- Safe unattended machine operation with integrated U/V Flame Sensor and Fire Suppression technologies.

- Ergonomic work tank access for user-friendly setups and easy automation integration with the programmable 3-sided rise and fall powered work tank.

Touchscreen control

Makino EDMs stand apart with the intuitive Hyper-i control system, a streamlined and efficient interface that helps you get work done faster. A large high definition 24” touch screen functions like a smart device (phone/tablet), allowing operators of all skill levels to benefit from its inviting and familiar operation that substantially reduces training requirements. The Hyper-i control further elevates an operator’s capability with several integrated advanced functions, such as hyper-linked digital manuals and video tutorials, E-Tech Doctor, and EZ-Cut that deliver higher levels of productivity to the operator’s fingertips.

Makino offers a range of Sinker EDM machine solutions.

EDAC-Series

EDAC-Series machines are ultra-micromachining products. With pinpoint sub-micron precision and outstanding surface finish, these are ideal for small electronics and micromachining applications.

EDAF-Series

Ideal for Die/Mold applications, the EDAF-Series combines speed, high accuracy and excellent surface finish capability. This machine uses a stationary worktable with a rise and fall work tank for easy access and simple automation. A highly versatile Fine Hole configuration is offered that enables both standard Sinker EDM and high accuracy EDM Drilling operations on a single machine.

EDGE-Series

The EDGE-Series is ideal for general precision machining needs. Effective and reliable performance combine with an ergonomic layout to drive efficiency. A dielectric reservoir and ATC (Automatic Tool Change) unit is built into the base casting to minimize floor space.

EDNC-Series

The seven EDNC machine models bring similar capabilities as the EDAF-Series but with larger platforms to accommodate a wider range of workpiece sizes. Machines can be equipped with the HS-Rib high speed jump Z-Axis to be as productive and accurate as smaller machines.

Learn how Makino innovation is driving production

Makino is the world leader in EDM (Electrical Discharge Machining). With more than 140 patents, a Makino EDM means faster processing times and superior surface finishes for even the most complex part geometries. See how Makino turns innovation and technology into increased production and a lower cost per part for our customers.

Sinker EDM Machine Line-up

|

|

MACHINE SIZE |

| Small |

<------- |

Medium |

-------> |

Large |

|

Micromachining

Position Accuracy: +/-1.0μm

Best Finish: 0.03μm Ra (1.0μinRa)

|

|

|

|

|

|

|

High Precision/Fine Finish

Position Accuracy: +/-1.0μm

Best Finish: 0.05μm Ra (2.0μinRa)

|

|

|

|

|

|

|

General Precision

Position Accuracy: +/-2.0μm

Best Finish: 0.3μm Ra (12μinRa)

|

|

|

|

|

|

|

General Precision/ Large

Position Accuracy: +/-5.0μm

Best Finish: 0.3μm Ra (12μinRa)

|

|

|

|

|

|