Most wire EDM machines chew through more than one pound of wire per hour, making wire consumption the biggest expense of operating a wire EDM. Makino wire EDM machine uses half that, providing a significant long-term savings in $1,000’s of dollars per year in operating cost.

The wire consumption unspool speed on a Makino wire EDM is set to a constant low rate where optimal machining speeds can be maintained without the wire breaking. Makino has also developed a unique adaptive control technology called BellyWIZARD which automatically compensates and adjusts the wire mechanically based on work piece thickness to ensure the best part straightness and precision while incorporating the advanced HyperDrive wire transport and tensioning system.

Our wire EDM machines utilize a unique fully digital dual flush pump configuration that provides automatic dynamic adaptive control of flushing to the Upper and Lower machine heads in real-time during operation. This intelligent and highly effective configuration provides double the horsepower in flushing capacity and ensures that the necessary flush is applied optimally to when and where it is needed for best performance and productivity.

Other Makino wire EDM machining advantages include:

- Up to 50% less maintenance, which is a critical benefit compared to the usual high-maintenance requirements associated with wire EDM production. Makino wire EDM machines also have less consumable wear parts.

- Large HD Touchscreen control that works like a smartphone. Operators of all skill levels can use this streamlined interface that reduces machine training requirements. Only Makino can provide the advanced Hyper-i control that provides an identical productive interface for all Makino wire EDM, Sinker EDM, and EDM Drilling machines, which further reduces training support needs.

- Easy automation. Get predetermined optimized settings for any application and 24/7 production with no attendant required.

Touchscreen control

Makino wire EDM machines stand apart with the intuitive Hyper-i control system, a streamlined and efficient interface that helps you get work done faster. A large high definition 24” touch screen functions like a smart device (phone/tablet), allowing operators of all skill levels to benefit from its inviting and familiar operation that substantially reduces training requirements. The Hyper-i control further elevates an operator’s capability with several integrated advanced functions, such as hyper-linked digital manuals and video tutorials, E-Tech Doctor, and EZ-Cut that deliver higher levels of productivity to the operator’s fingertips.

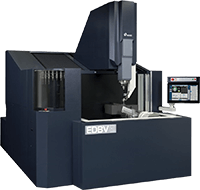

Which Makino EDM machine is right for you?

Makino offers a wide range of wire EDM machine solutions.

UX-Series

All machines feature the HyperDrive Extreme Wire Guide System which provides greater tensioning precision as well as Jet-less threading capability. Dual independent flush pumps with H.E.A.T. Technology is standard on all machines.

U-Series

All machines feature dual independent flush pumps with H.E.A.T. Technology standard. The U-Series includes wire EDM machines that feature a 3-sided rise and fall work tank for easy access to the work zone and simplification of automation.

UP-Series

The UP-Series includes machines utilizing oil-based dielectric that further improves work piece surface finish and metallurgical quality. The series also includes machines designed for micro machining utilizing fine wire down to a diameter of 0.015mm (0.0006”).

Learn how Makino innovation is driving production

Makino is the world leader in wire EDM machining. With more than 140 patents, a Makino wire EDM machine means faster processing times and superior surface finishes for even the most complex part geometries. See how Makino turns innovation and technology into increased production and a lower cost per part for our customers.