A-Axis

- Digital Makino

- Machine Technology

- Support

- Events

- Resources

- About Us

- Press

- Select a Language

- Tech Expo

- Distributor Login

- Financing

- Request A Quote

- Find A Rep

- My Makino

- Careers

- Contact Us

- Why Makino?

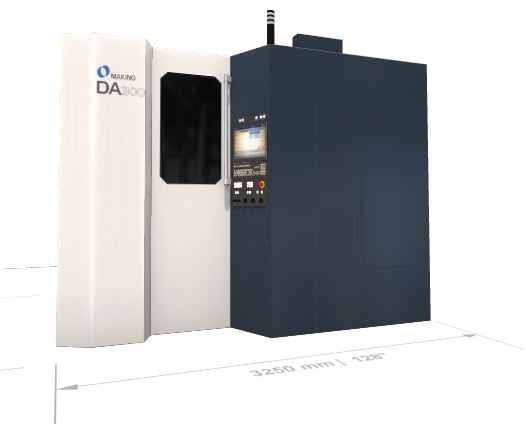

The DA300 is inspired by the best design characteristics from both vertical and horizontal machine platforms to deliver the highest productive capabilities for multi–axis workpieces in the very smallest of machine footprints.

These features make the DA300 ideal for single setup, multi–side accessibility, or full contouring capability to quickly and efficiently tackle a wide variety of complex production part applications – typical of industrial hydraulic & pneumatics elements, optical, electrical & semiconductor markets, medical & dental products, die – cast parts, automotive components, aircraft and aerospace parts as well as contract job shop work.

The Makino DA300 5-Axis Vertical Machining Center combines a rigid structure and high dynamic motion control to significantly reduce part cycle times while maintaining very accurate performance. Equipped with an integral, DD – motor designed A – Axis and C – Axis, the machine provides five – side access for single set-up production of complex production parts.

At 20,000 RPM, 29.5 HP, HSK–A63, the machine spindle provides the capability to tackle rigorous milling, drilling and tapping tasks associated with a wide variety of production parts. A standard, 60 tool magazine insures an extensive selection of tooling to address any part configuration.

To further minimize non – cut times, the DA300 is standardly equipped with a Vision BTS (Broken Tool Sensor) outside of the machine work zone to insure tooling integrity – but, not impact part cycle times.

The DA300 integral table rectangular table (340 mm x 300 mm) is prepared with pneumatic ports design to readily integrate into a pallet system providing for quick, efficient part exchange – maximizing machine utilization.

The Makino Professional 6 control takes you from parts to profits with elegant functionality by making the point where human meets machine a seamless transition. Streamlined screen layouts, operator assistance, new machine functions, and safety enhancements are accelerating and protecting your productivity. For even greater productivity, Super Geometric Intelligence 5 (SGI.5) insures optimum performance during execution of the tool path – producing the shortest cycle times.

Standard Features:

A-Axis

150° (+30 to -120)

C-Axis

360°

Spindle RPM

20,000 (HSK - A63)

Rapid Traverse

60,000 mm/min

Cutting Feedrate

60,000 mm/min

Maximum Workpiece

450 mm diameter x 400 mm (conditional)

Maximum Payload

250 kg

ATC Capacity

60 tools (118 opt)

Chip to Chip

3.5 sec

Maximum Tool Diameter

70 mm / 140 mm (ALL / ADJ)

Maximum Tool Weight

8 kg

Optional ATC Capacity:

Yes

A-Axis:

150° (+30 to -120)

C-Axis:

360°

Spindle RPM:

20,000 (HSK - A63)

Rapid Traverse:

2,362 ipm

Cutting Feedrate:

2,362 ipm

Maximum Workpiece:

17.7" diameter x 10.6 " (conditional)

Maximum Workpiece Size:

Stand alone - ø17.7" x 15.7", Manual with chuck - ø17.7" x 11.6", WPS - □14.0" x 11.6"

Maximum Workpiece Weight:

Stand alone - 551 lbs, Manual with chuck - 474 lbs, WPS - 177 lbs

Maximum Payload:

551 lbs

ATC Capacity:

60 tools (118 opt)

Chip to Chip:

3.5 sec

Maximum Tool Diameter:

2.76" / 5.51" (ALL / ADJ)

Maximum Tool Weight:

17.6 lbs

Makino.OptionalATCCapacity :

Yes

© 2024, Makino Inc. All rights reserved.